One repaired cheese press…

Archives

12

Oct 16

Repairs

I shouldn’t let four-year-olds near finished cheese presses 🙁

So he was spinning the handle happily and it generated so much pressure with the crossbar cinched down that the nut in the center broke its epoxy bond and pulled right out of the crossbar. Doh. And the pusher plate is epoxied at one end and the handle at the other. Double doh. So I think about it at work and eventually discount the idea of drilling a hole and soldering in a pin because really, you’d want to weld that and I have no welder. Also, metal droplets at several hundred degrees centigrade hitting all those wood shavings beside all those finishing chemicals… er, no.

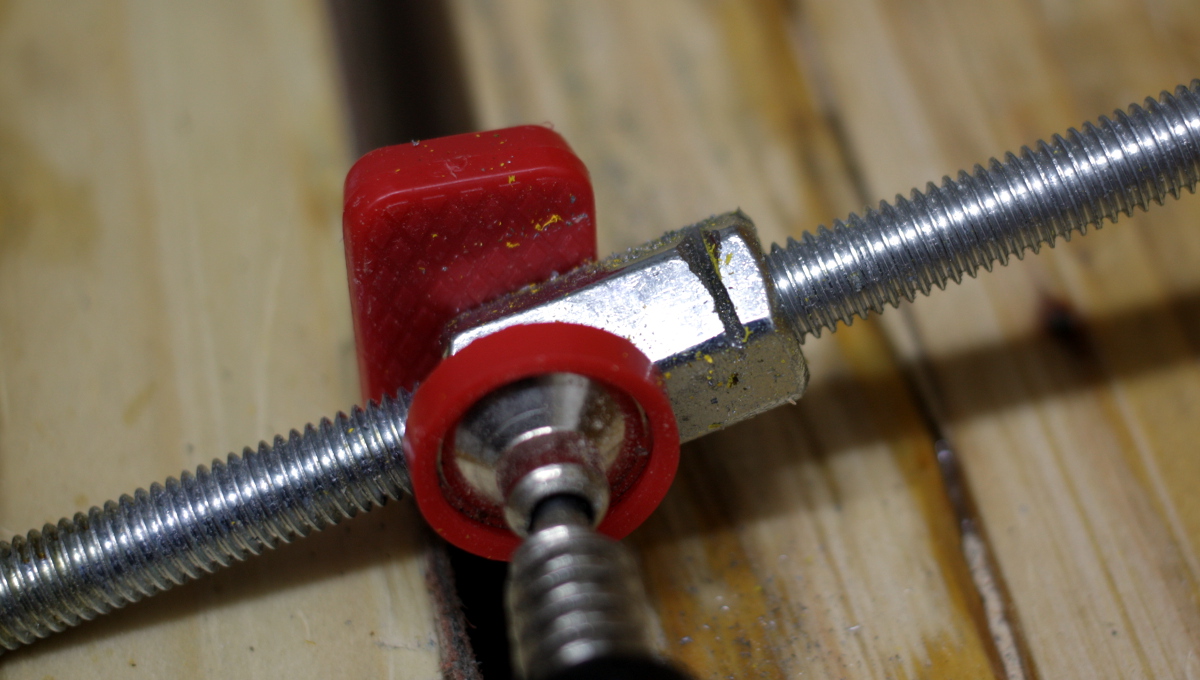

So instead I clamp a clamp in the vice (workholding for this was painful), and cut a slot in the nut with a hacksaw (a new fullsize one because that Draper dross was unusable) and widen it with a file:

This takes a while to do, but I have a cunning plan…

I had to get some brass for the cot anyway for drawer bearing surfaces, so I got a little extra and cut a small piece off it (the rest will get used in a few other things). I couldn’t find any JB weld, but I could find an araldite metal epoxy, so I mix up some of that, fill the slot with it, shove the brass in, slather some more epoxy on that, and then swear many, many times at all my clamps as they all fail to clamp it in place, and I eventually resort to tape.

I’ll give that a few days to cure and then I’ll cut a fairly precise (ha!) mortice in the crossbarwith the marking knife and a small chisel and epoxy the nut and the bar back into the crossbar. Hopefully that will act as an anchor for the nut in the crossbar. We’ll see…

Then on to the slats and thicknessing.

It’s very simple. You put the slat in the jig, you put the plane on the slat…

…then you push the plane back and forth until the slat is at the right thickness…

…then you push the plane back and forth until the slat is at the right thickness…

…or until the blade of the plane chatters, catches on the slat because the slat is slightly bowed, and smashes through and over the stop at the end of the jig destroying it. Oh, bother.

Well, what good is a planing stop that can’t act as a stop when planing, right?

/sigh

Still, it worked and let me get on with it. So now I have four slats planed to thickness and with squared edges (though there’s some slight bowing…)

11

Oct 16

Done

So first off, a small message to Draper. Don, you’re a very sad individual. And now a message to Draper, the tool company. This sucks:

Yeah, it’s a junior hacksaw, but the operative word here is saw and I think you could almost be sued for false advertising for calling this piece of worthless dross a working saw. It’s for the bin, and I’ve now got to go find a decent hacksaw to work on saw sharpening. Ugh.

Anyway. That pain in the toolbox aside, the cheese press is now done. It came out too tall yesterday so I trimmed it down a bit last night and then did the finishing. Four coats of shellac, cured overnight and then some briwax and buffing the next day. Then I assembled everything, epoxied on the pusher plate on the main screw and added some feet to the base and that was that.

I’m not saying this is fine furniture, you understand – in fact, to manage expectations, this is what this started out like last thursday:

And in the meantime I’ve painted the shed (twice) and finished off the resawing of the slats for the cot. And today the cheese press looks like this:

I mean, it’s not horrible for a pair of 2×4 offcuts and a short length of threaded rod.

Anyway, wee man was a bit ill today so no real shed time; I did get to go out for a half-hour or so, and clean up after the press and set up for planing the slats.

Someone asked – the thicknessing jig is the width of my #5½ plus a quarter-inch between the walls (and I really need to cut a 45° angle on the near walls to stop myself barking my knuckles on them) so it rides happily on the rails without being slewed. It’s butted up against the planing stop on one side and against a batten&holdfast at the back:

In operation it’s quite simple – put the slat blank into the center, put the jack plane on top of it, shove jack plane to the far end, repeat until the jack’s not cutting anymore (flip the board at some point to be sure you have two reasonably smooth sides). You can optionally hit it with the smoother towards the end if you want.

Twenty slats (well, nineteen since I did #1 already at the start) to thickness, and then plane to get their edges square. This is going to be my planes’ eye view for a while I think…