It’s been one of those consumer weekends so far. Friday was the trip to the timber yard (and would have been another trip to go buy a plastic drum for dust collection, but they weren’t open); and today was a trip to B&Q to buy one of these:

Yeah, I know, it’s plastic, but it’s cheaper than you could build one for. Tomorrow the lawnmower and garden tools and a lot of this muck are going in there:

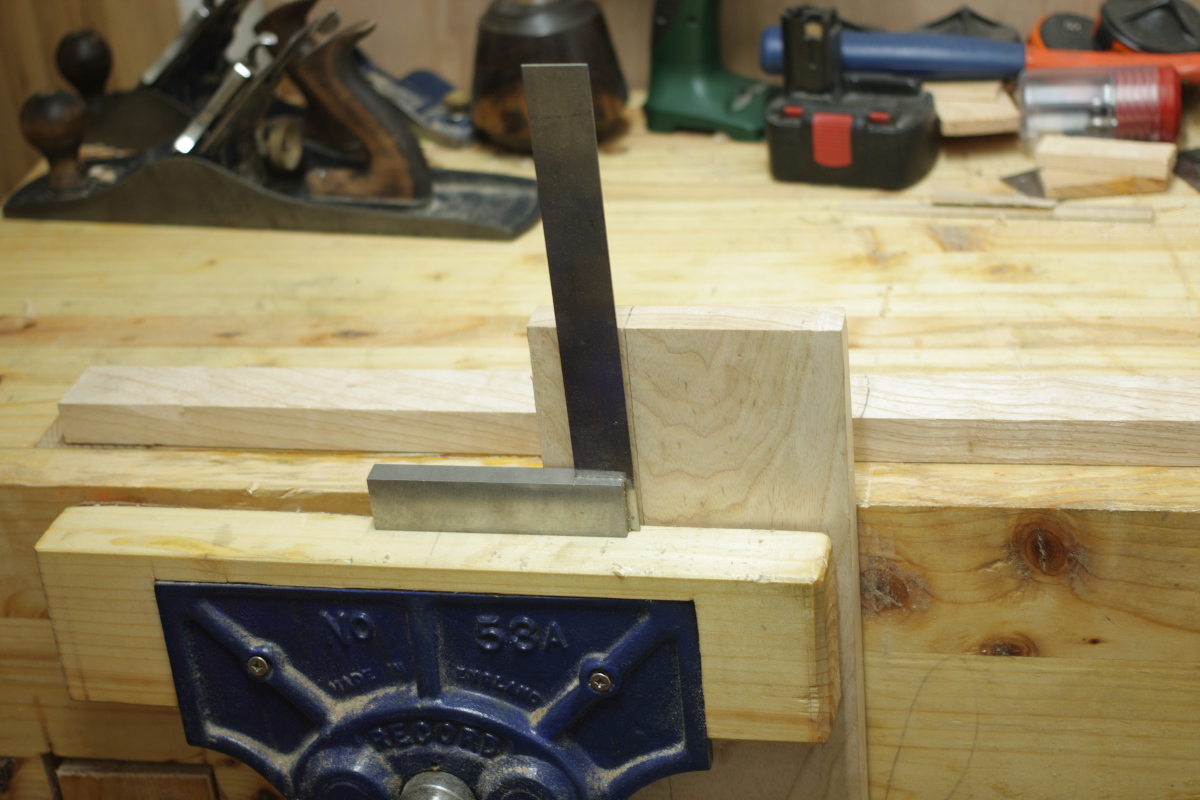

After that, I might be able to actually stand in front of the vice for rip cuts…

And then there was the testing of the mattress for the cot, for which we roped in a volunteer…

It was deemed to have passed inspection.

And lastly, I solved yesterday’s storage problem with the vigorous application of a circular saw (yeah, yeah, power tools, I’m unclean), and now I have a stack of rough-cut parts for two or three projects.

There are still a few 5′ and 6′ boards to stack, but I can manage those, just about.

And with any luck, I might get back to project work tomorrow sometime, and get the steaming jig rebuilt, a drying jig built, and if I’m fast, get one of the walnut frame pieces steamed and bent.