Just not a very productive Sunday really. Checked my squares, found one is so not square that I threw away the crosspiece and I’ll use it as a straightedge from now on.

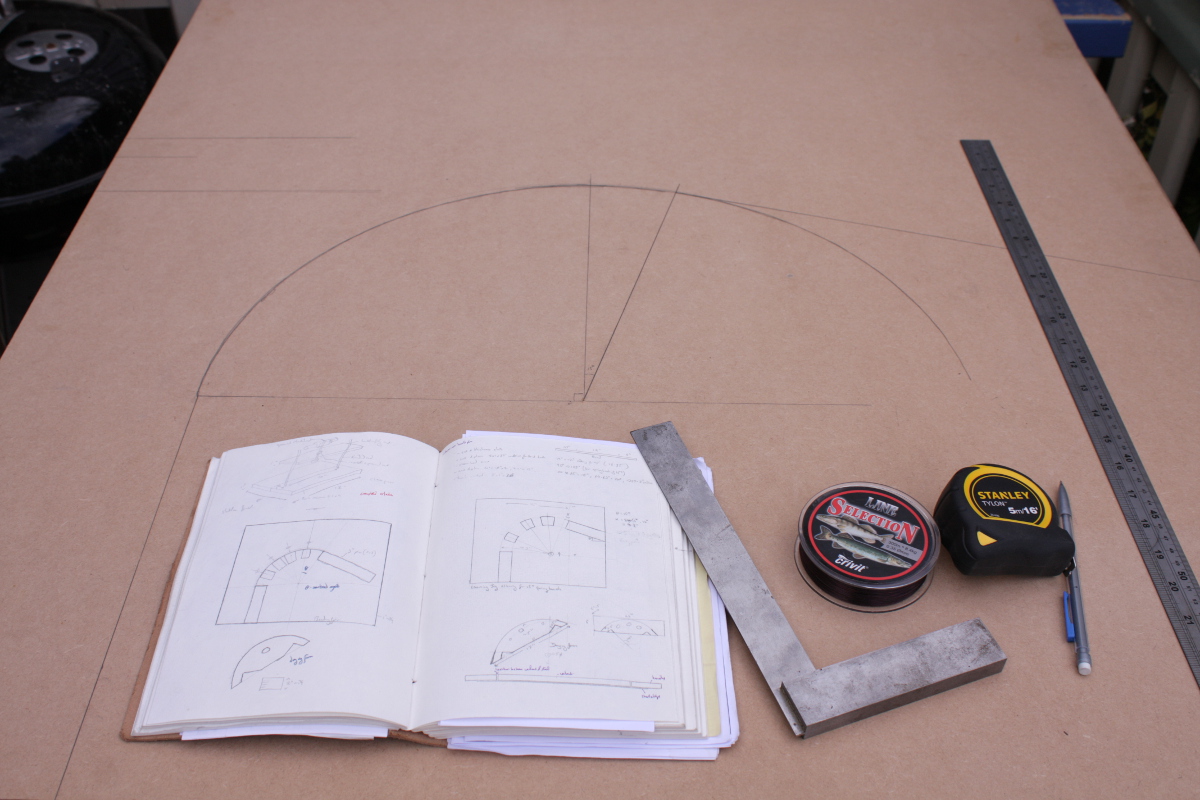

Then got on with building the jig. Laid out the geometry (a 10.3″ radius curve gives a 12″ radius curve and 15 degrees of springback).

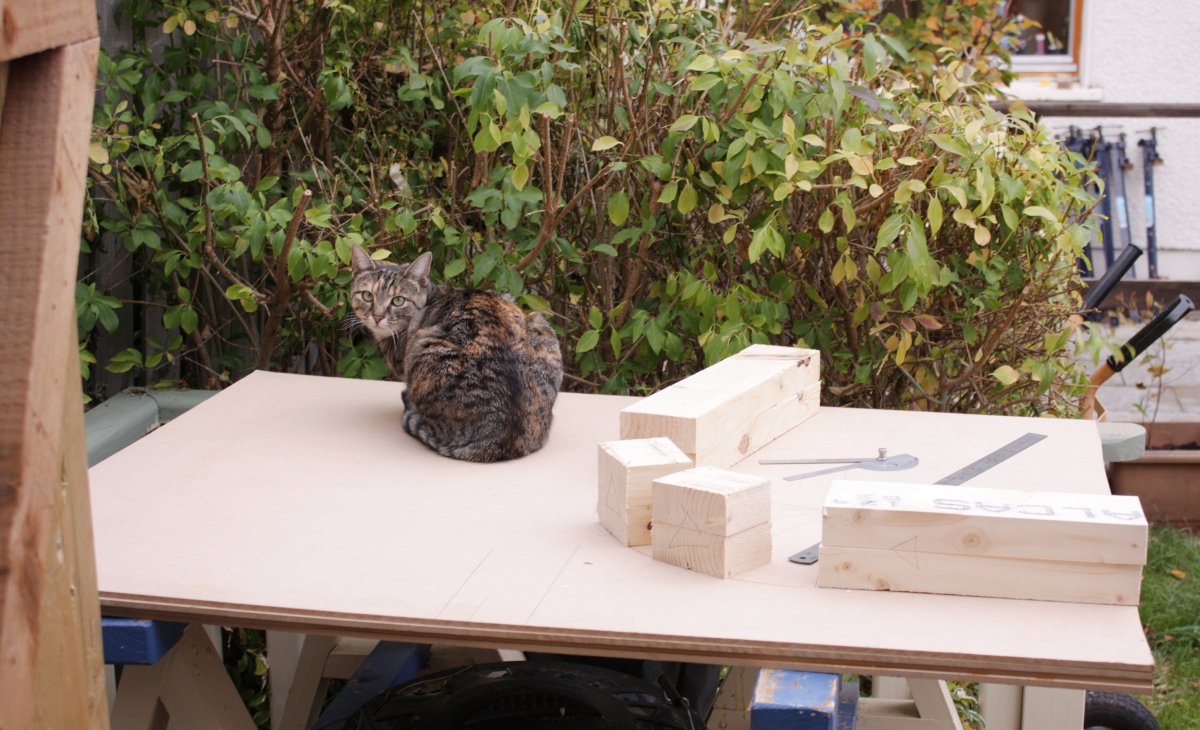

Shop cat is somewhat critical of the layout…

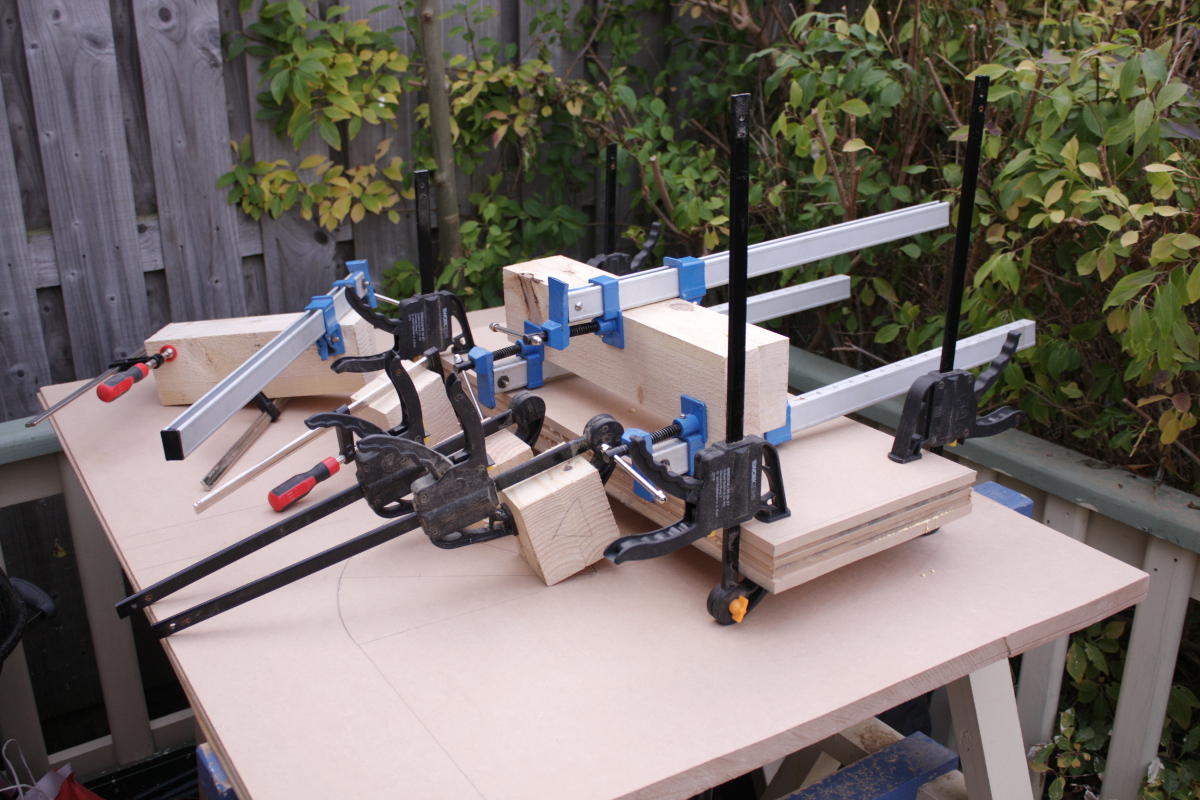

Laminating MDF to make a drying form (which will have the 12″ radius and the walnut gets clamped to this for a week after it’s had a day or so on the bending jig to cool).

Lots of laminated MDF and 2×4 chunks. This is when you not only have insufficient clamps but also insufficient space to put the drying bits 😀

I thought it was a bit of a gimmicky thing when I bought it, but those silicone glue brushes work damn well. Worth every cent (especially when buying them from Rutlands in the UK instead of buying the Rockler ones from the US).

And last job, fixing and reattaching the vice jaws (finally – shop jobs seem to be cobbler’s children really).

Simple enough job, just counterboring for nuts and ensuring they were below the surface of the face. Complicated only by not having a drill press or fostner bits, but an auger bit and brace and a little fustering sufficed.

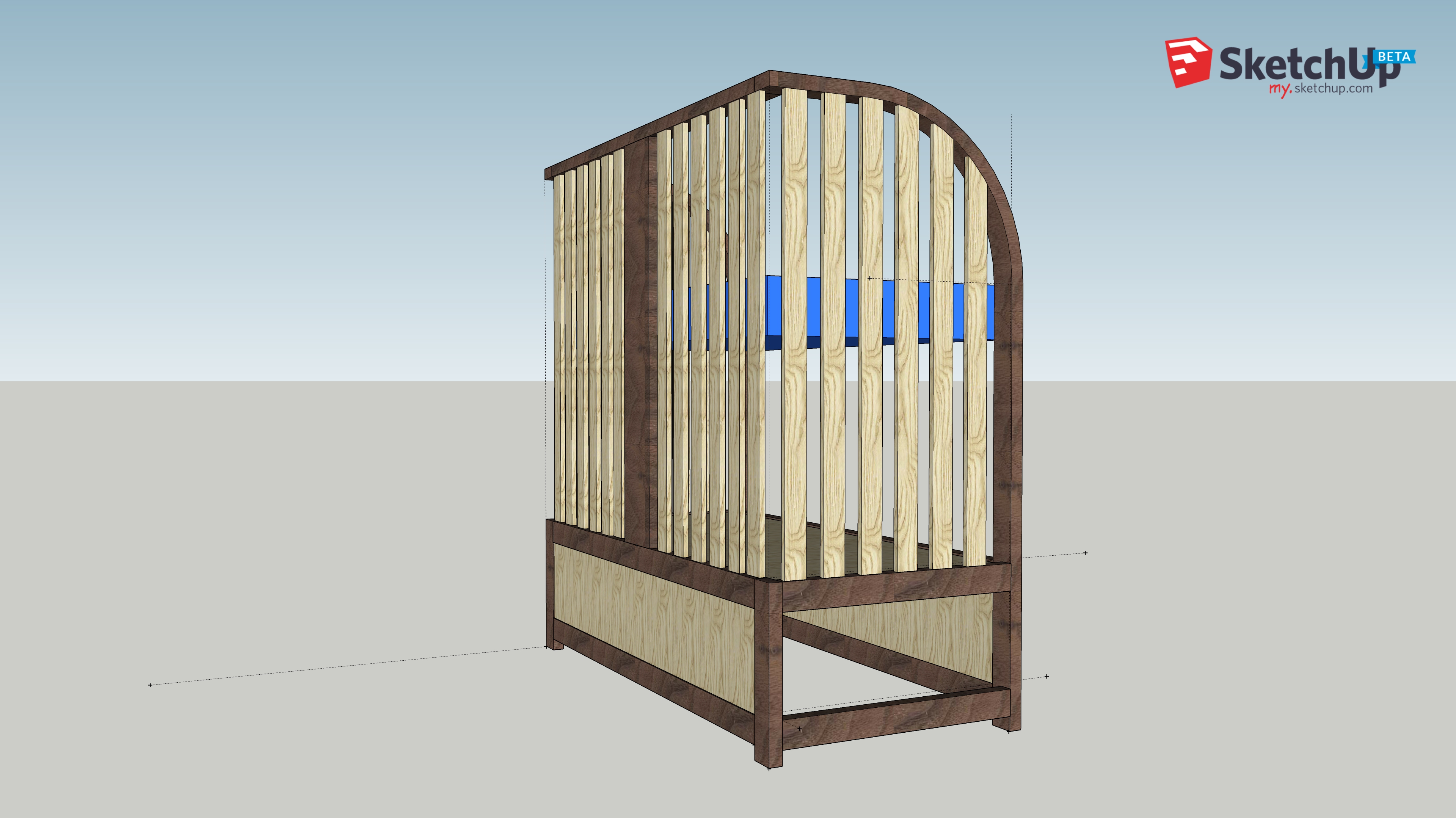

Then went through the stock in the woodpile matching pieces to cutlists and finding that for the largest panel in the crib, I don’t have long enough boards to do lengthwise glue-ups in the panel. Hmmm. Is it okay to run the glue-ups crosswise I wonder….