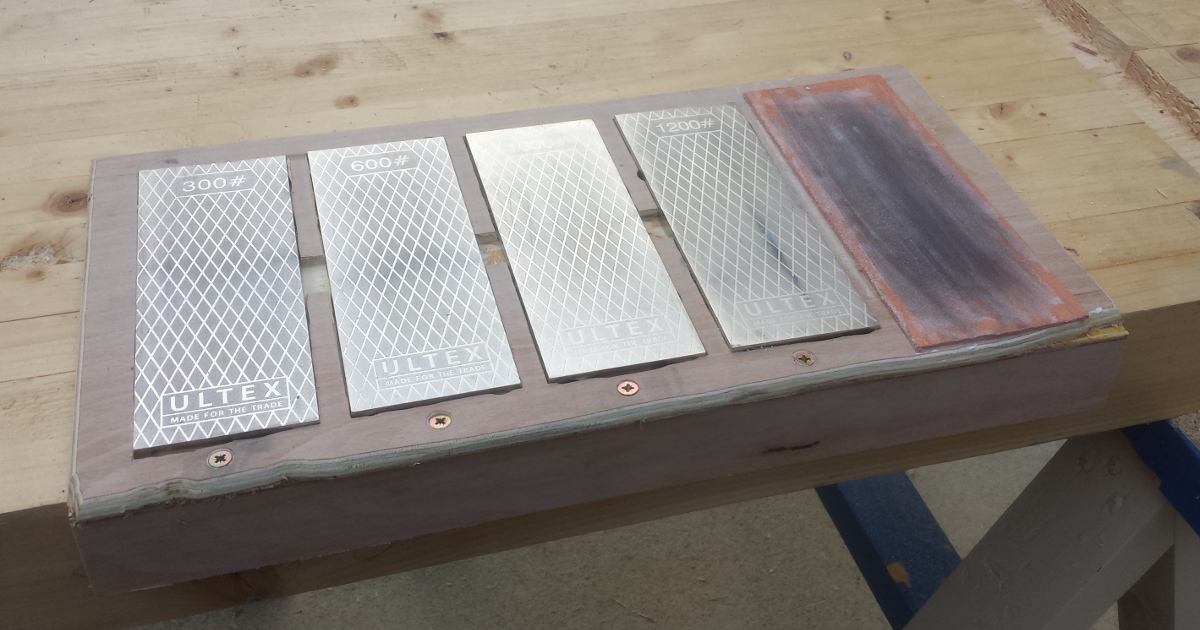

Small bit of work which was actually done during the bench build. If you’ve seen any of Paul Sellers’ videos or either of the two blog posts on this, or that Wood by Wright video, you know what this is. And since ITS.co.uk were having a sale of Ultex diamond plates for £10 each I could afford a full set, so I wanted them in a single place that would make it easy to sharpen stuff on the fly.

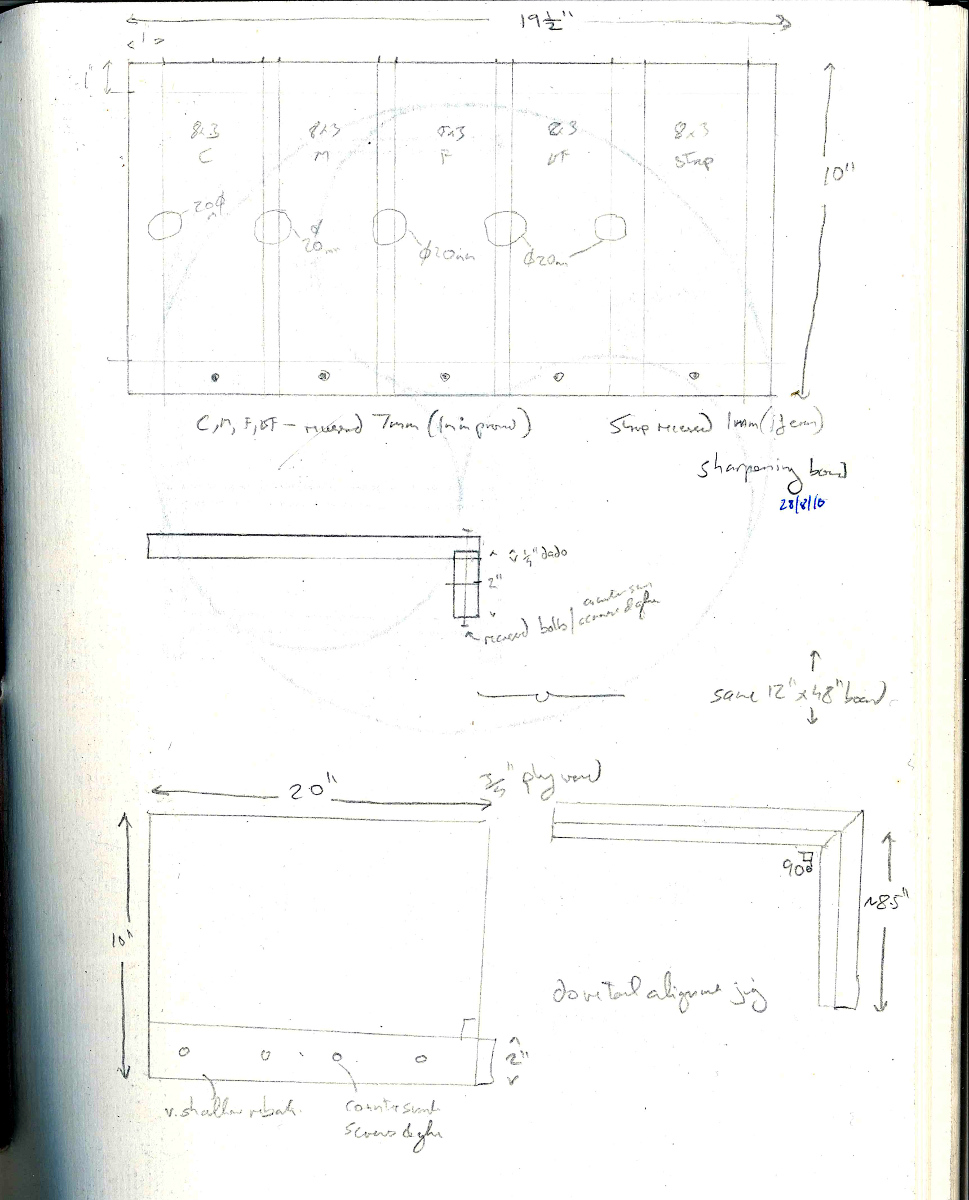

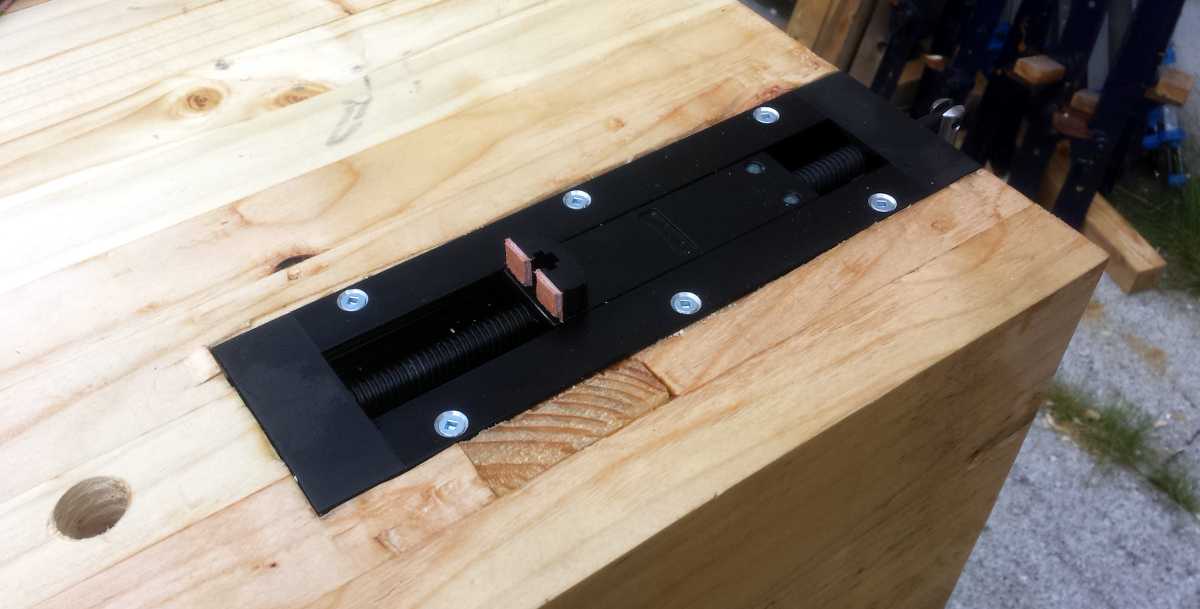

Simple enough idea that it only takes up half a page in the notebook. Basically, take a bit of plywood, use a power router to carve out four holes in it a few mm deep, square and trim those with a chisel, leave cutouts between the holes for finger access to remove sharpening plates for special cases like hand router bits, and put a strop on one end as well. Also have a small rebate in the front underneath so you can put in a small batten for the vice to grab onto. (The other idea you see on the bottom of the page is one of David Barron’s dovetail alignment jigs in plywood, I have the bits cut but not yet assembled). All of these are rough jigs in plywood, btw – they’re more the jigs you use to build the better jigs if you know what I mean.

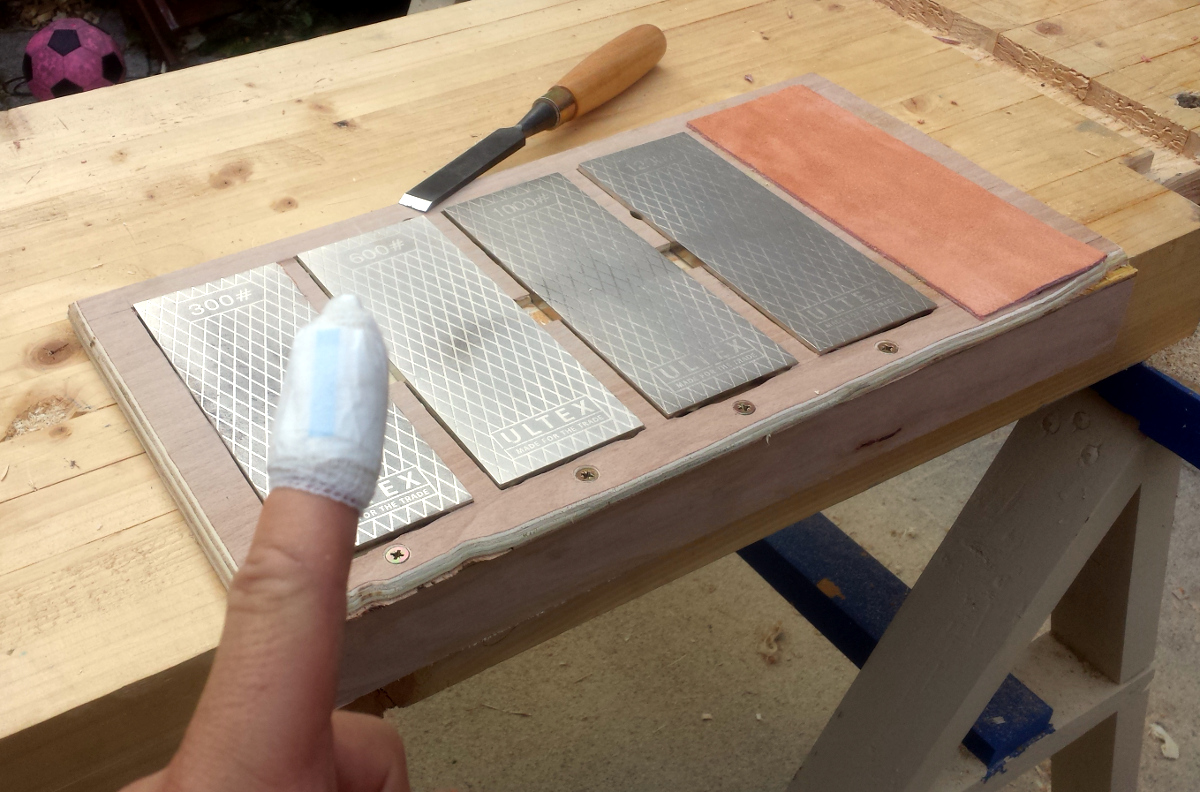

Wasn’t even all that hard really, even if the router got away from me when rounding over the edges (hint: router bits with edge rollers don’t do well if you’ve removed the bit they run on for the rebate…). Definitely not perfect, and needs redoing in real wood (the plywood shears too readily and it’s not the tightest fit for the stones), but it’ll do for a few months and help me build the proper holder later on.

Small note though – when squaring up the holes for the plates, be careful. Chisels are sharp…