Two more nights in the woodturning class since last time. And I’m still not dead, which has surprised everyone.

Lay off the jokes, it’s a dibber. You stick it in the ground, wiggle it about to make a hole, drop in a daffodil bulb. The burn lines indicate how far down you’ve gone becuase that matters for some bulbs (specifically, the ones you want to not rot in the ground). Sanding on a lathe btw, is immensely fun, because you just hold the sandpaper and the lathe does the work. Holy hell is that better than sanding a resin&walnut desk….

And then this week….

Yes, that thing was a branch in Marley Park the morning before. Green wood. Fantastic to work with, like cutting cheddar cheese. Woodcarving videos of green wood are now ruined for me, those lads are just cheating 😀

Tapered head…

Turn a handle and put in some burn lines for fun…

Check the fit, refine it a bit…

And that’s it done. And I needed a new carvers’ mallet because I only have two of those and three other mallets (and a few hammers).

And then of course, the part woodturners don’t tell you about…

I’m going to have to figure out how to cope with this in the shed 😀

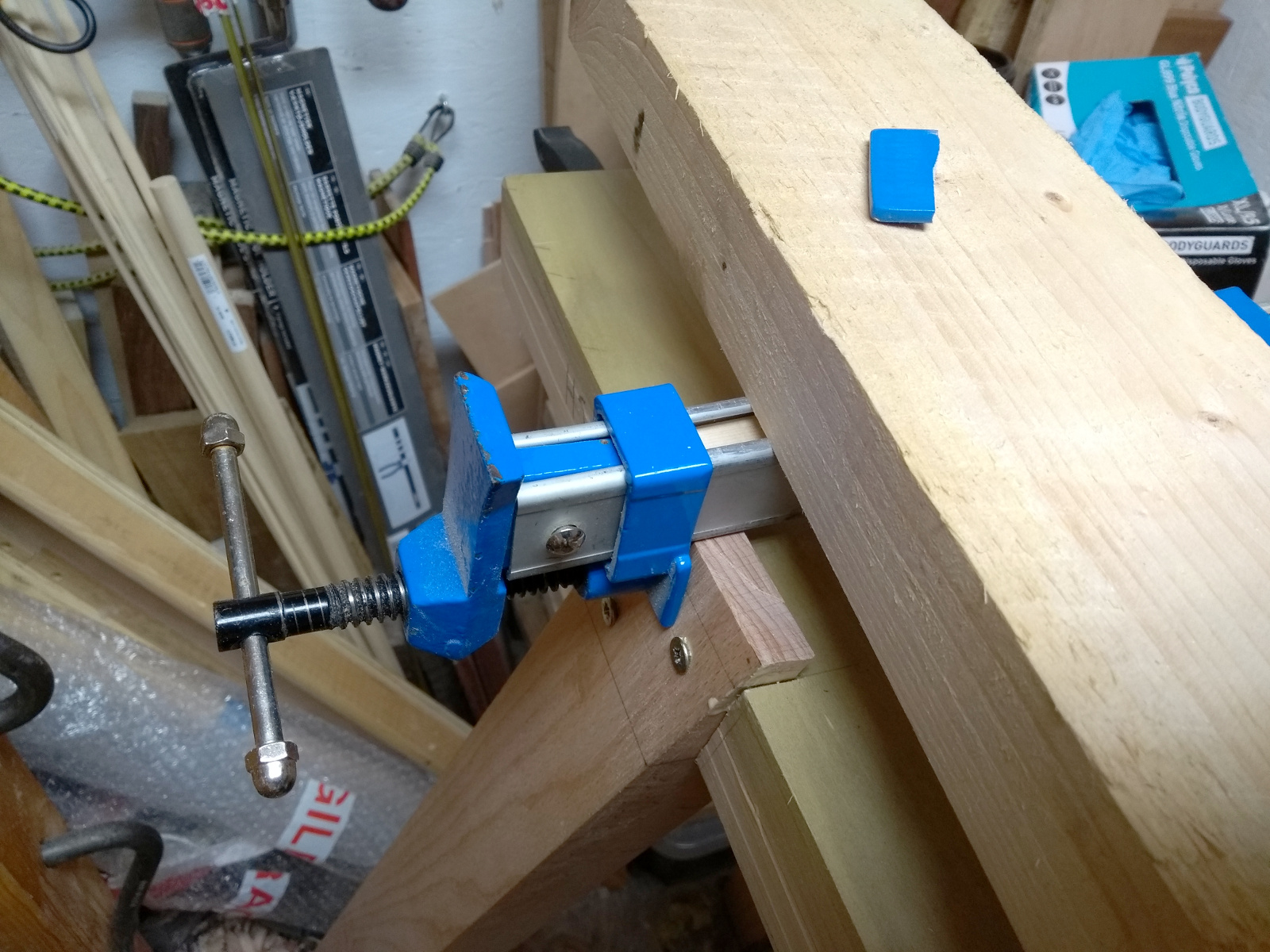

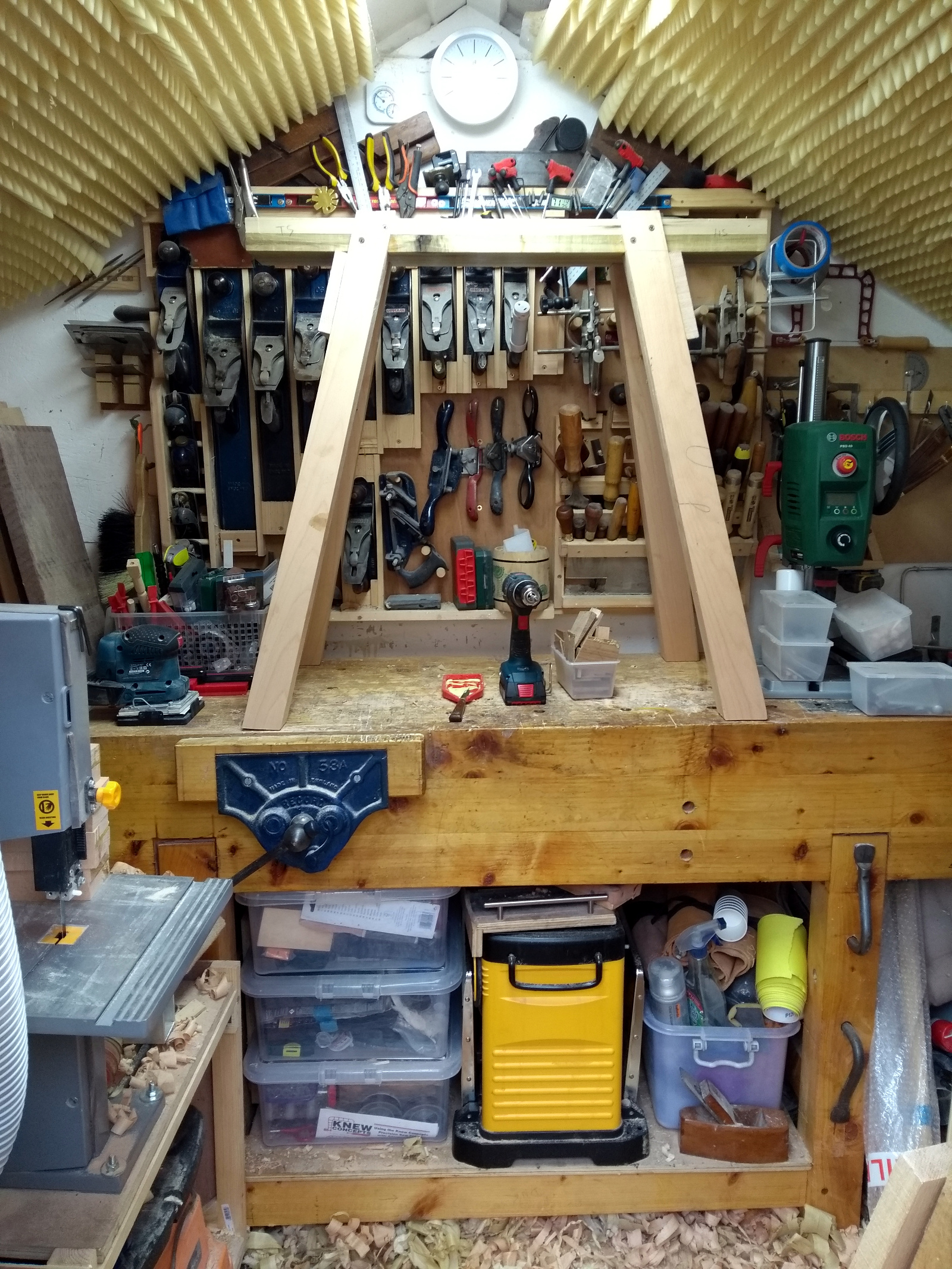

Meanwhile, the lathe stand progresses. I got the compound cuts in the legs and crossbar done.

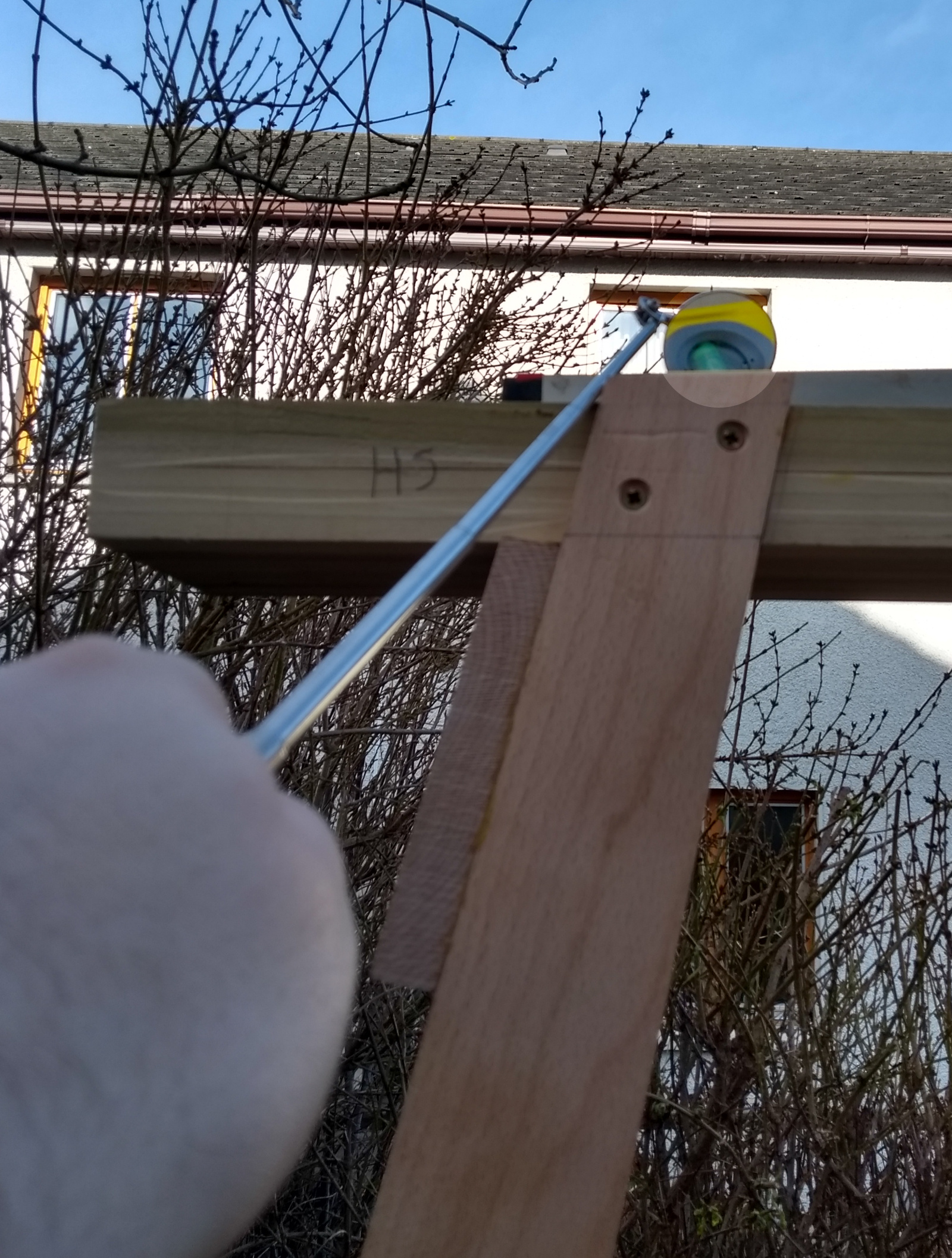

Then once that had cured, out of the clamps and out of the shed to get levelled.

First level the MDF on the sawhorses, then level the legs with shims so that the spirit level says flat on both the MDF and the crossbar of the stand.

That’s a wee bit tall to check the spirit level btw, so mirror-on-a-stick came in useful…

So with the legs marked, out with the ryoba and cut to the line and a bit of chisel-paring for the bits where I missed the line, and…

And built up the webs (which were already 3/4″ beech) with offcuts and glue and screws to make that whole area into a solid block for stability.

And it’ll have stretchers under the feet to lock them at the bottom and I can optionally screw the stretchers to the floor if I have to. I might have to, lathes vibrate a lot…

And while it’s still not done (cheers Storm Ciara and having to go vote), I do get to take my new toys to turning class tomorrow night…

Cheap and cheerful set from Rutlands. Now I need to finish the lathe.

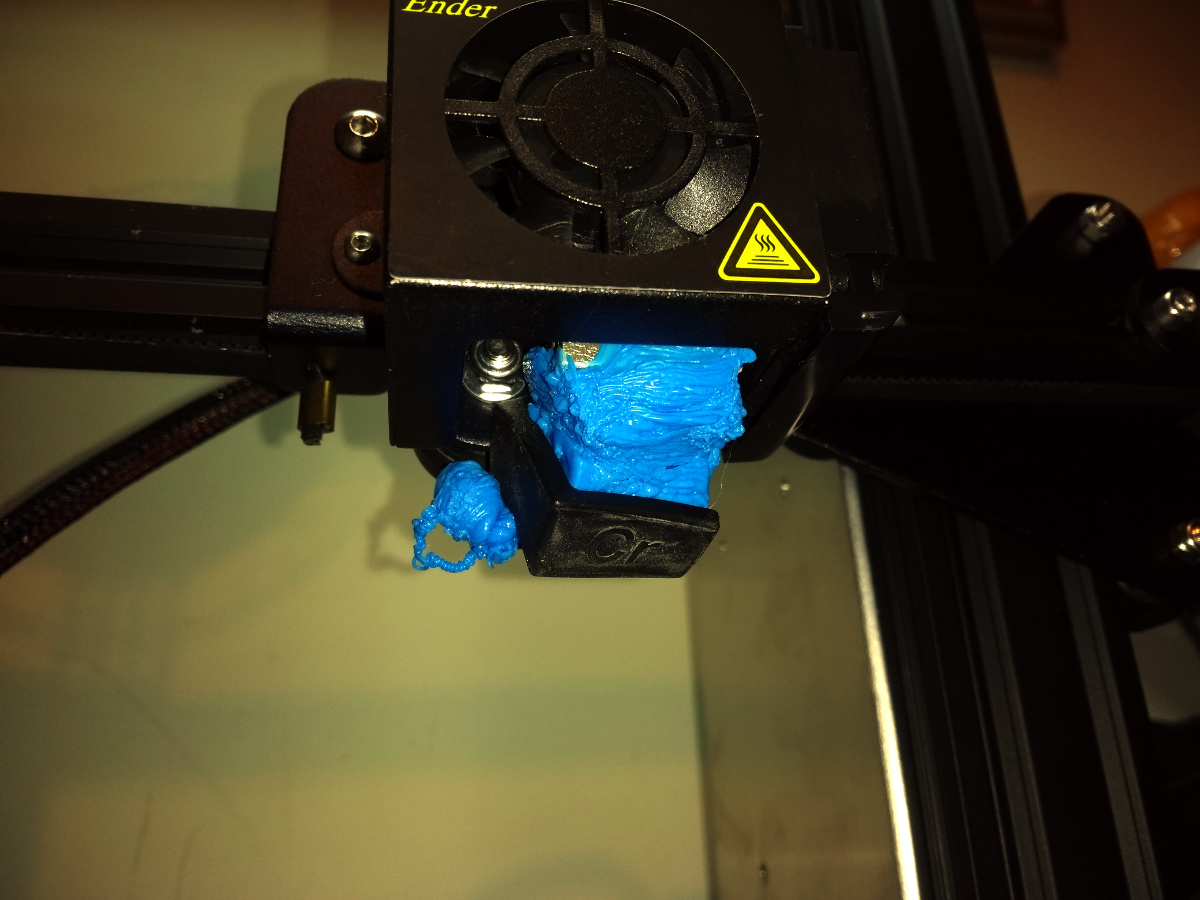

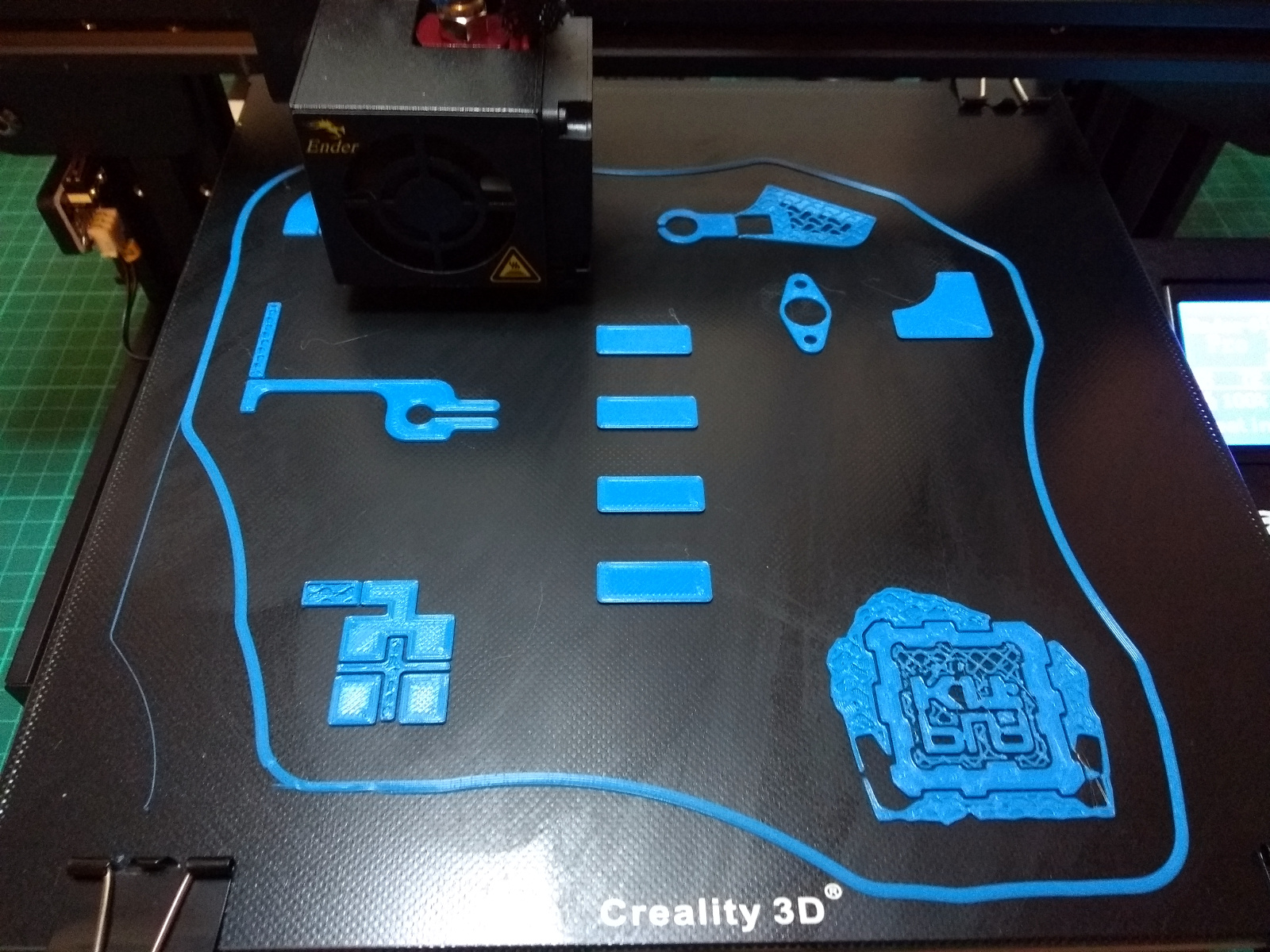

And maybe get some stuff printed for the shed on the 3D printer, but I’m having issues with that at the moment.

That took almost an hour to clear. Jaysus. And it did it again on the next print so I obviously didn’t get it right either. Le sigh. And that was *after* I’d bought it a new tempered glass bed.

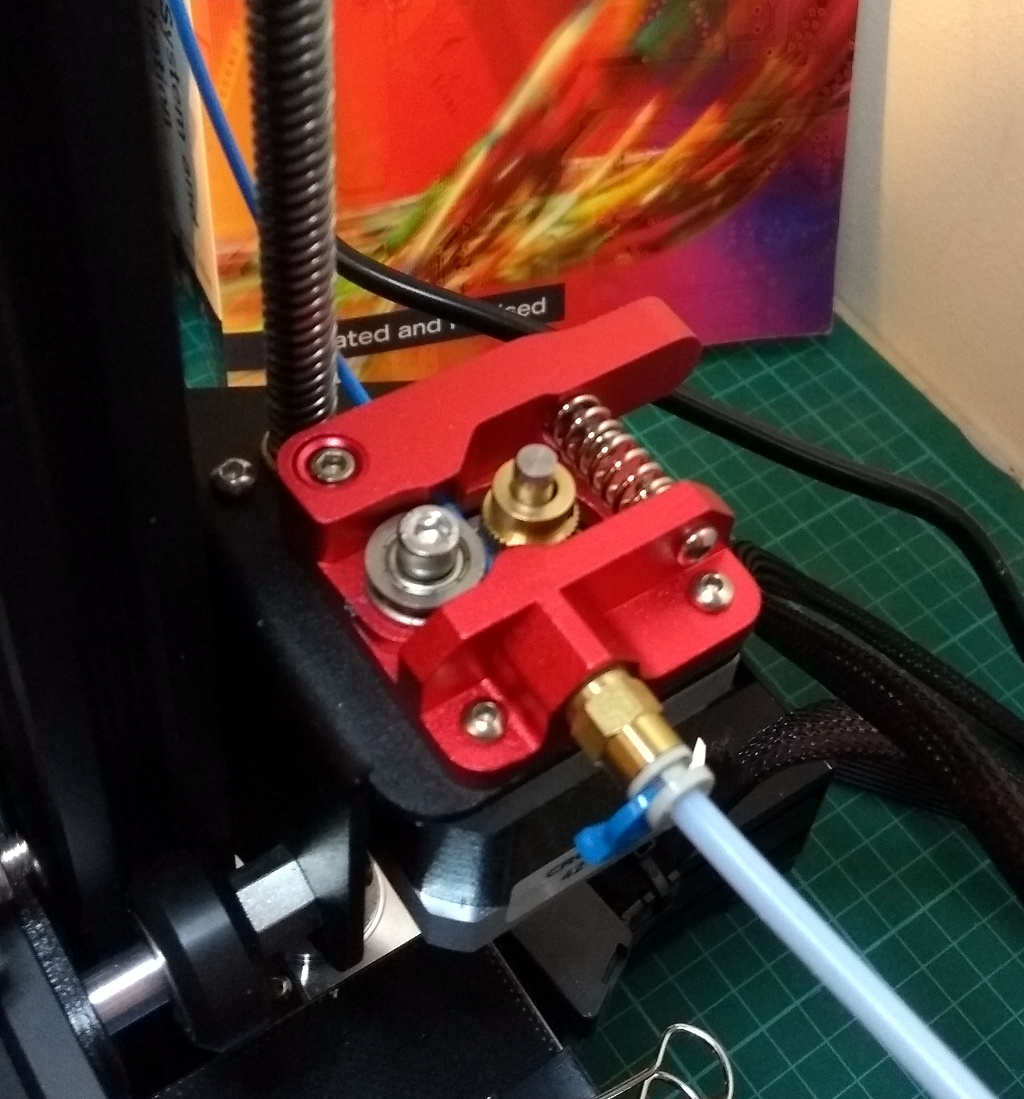

And a new aluminum thingy for the extruder feeder yoke.

It can be a tempermental little bugger, so it can. And it might just be the filament, I’ve heard that some people found this stuff to be a bear but if you bought decent filament all the issues went away. Well, I guess we’ll see…

Tags: 3dprinter, beech, ender3pro, lathe stand, oak, poplar, rutlands